Quick Guide to Anti-Slip Safety Compliance

.png)

- Are anti-slip solutions mandated by law?

- Specific standards for different flooring surfaces

- Common slip hazards

- Common trip hazards

- Which floor types (surfaces) need anti-slip solutions

- Where to use anti-slip products

- More anti-slip FAQs

Are anti-slip solutions mandated by law?

When it comes to slip resistance compliance, always err on the side of caution.

If these work health and safety (WHS) statistics fail to convince you to install anti-slip solutions where your staff and customers walk, perhaps your legal duties will.

Yes, as a business owner, you have a general duty of care. Put simply, you have WHS responsibilities.

As we’ve emphasized in our slip resistance compliance guide:

Slipping, tripping and falling are risks that can be associated with steps and stairs, and can lead to serious injuries. Under the WHS Act, the employer has a ‘duty of care’ to provide and maintain a safe and healthy workplace – all potential hazards must be identified, the associated risks assessed and then controls introduced to eliminate or reduce those risks as far as practicable.

(Make sure to get your free copy of the guide here.)

Your responsibility extends to making sure your customers, visitors, and any contractors are safe at your business premises.

It is prescribed by Australian Standard AS1428.1 and a mandatory compliance requirement under the Building Code of Australia.

Disclaimer: AIMS is not a WHS law expert, therefore the information provided here should be treated as general in nature and not be treated as specific, legal or professional advice. Our article about WHS laws only aims to compile resources that may be helpful to your business. Official sources of information are cited.

Specific standards for different flooring surfaces

Standards Australia has a compilation of the prescribed minimum slip resistance requirements for different flooring surfaces.

Here are the links for your convenience:

Common slip and trip hazards

You can refer to this comprehensive fact sheet from Safe Work Australia (SWA) when trying to identify what may possibly cause a slip or trip accident.

For your convenience, we’ve simplified SWA’s list below.

- Spills of liquid or solid material

- Wet cleaning methods

- Wind-driven rain or snow through doorways

- Sudden change in floor surface (eg. joins between carpet and polished timber)

- Change from a wet to a dry surface

- Dusty and sandy surfaces

- Ramp incline

- Bumpy/Loose flooring

- Poor lighting

- Use of unsuitable footwear

- Ridges in floors or carpets

- Worn floor coverings

- Broken tiles

- Cracks and potholes in floors

- Changes in floor level

- Thresholds and doorstops

- Floor sockets and phone jacks

- Cables from power extension units

- Loads that obstruct vision

- Obstacles in traffic areas

For more information, be sure to read our article about how you can prevent slips, trips and falls in the workplace.

Which floor types (surfaces) need anti-slip solutions

SWA’s fact sheet has a quick guide to help you figure out which kinds of surfaces get slippery in what situation:

| Floor Type | Characteristics |

|

Concrete |

Rounded aggregate can be slippery when concrete wears. Interior surface is often sealed to prevent dusting and absorption of liquids - this can increase slipperiness. |

|

Terrazzo |

Gives good appearance and wears well but can be slippery when wet, when excess polish is used or when dusty. |

|

Quarry tiles, ceramic tiles |

Low water absorption and good resistance to chemicals. Slippery in wet conditions if smooth, but can be moulded with aggregate or profiles to improve slip resistance - special cleaning equipment may then be required. |

|

Glazed ceramic tiles |

Slippery when wet, particularly with soapy water. Some slip resistance treatments available, but preferable not to install these tiles on floors. |

|

Vinyl tiles and sheet |

Easy to clean. Use sheet form where frequent washing is required to avoid water getting under tiles. Slippery when wet, particularly if polished, however slip resistant vinyls are available. These have aggregates moulded in. Thicker and softer vinyls are more slip resistant than hard ones. |

| Cork |

Must be sealed to prevent absorption of oil and water, but may then be slippery when wet. |

| Steel plate |

Tends to be slippery when wet or oily, particularly when worn. |

| Rubber |

Less effective in wet conditions. Must be fixed down well at the edges and joints or will cause a trip hazard. |

| Plastic matting |

Interlocking PVC extrusions give good drainage and slip resistance. Hose down or steam clean. |

| Carpet |

Carpet has a shorter life than hard floor surfaces, but it can be a cost-effective solution. Installations should be wall to wall, to avoid the hazard of a trip on edges. When used in small local areas, such as at entrances, it should be installed in a recess in the floor. Alternatively, it should be rubber-backed and with hardwearing tapered edges. Trolleys can be harder to push on carpet, but if larger wheels are fitted and the carpet does not have a deep pile, this is not a serious problem. |

| Fiberglass gratings |

This product can have grit particles moulded into upper surface to provide very good slip resistance. Fluids are quickly drained away. |

Where to use anti-slip products

Standard anti-slip products are installed in relatively familiar pedestrian locations:

- Ladders rungs: The mostly smooth and often small foot surface area on ladder rungs present an extremely high-risk hazard that needs to be made safe by being covered with anti-slip material as specified in AS1657. Here are more reasons why ladder rung covers are essential for safety.

- Landings, platforms, ramps and walkways: Even flat surfaces can become slippery when left oily, overly polished or wet. That's where you need safeplates to ensure firm footing.

- Steps, stairs and stairwells: Slips, trips and falls on stairways are a more common occurrence in industrial and commercial environments than they should be, sharing about the same frequency of incidents being reported. Consider installing stair nosings in those places. There are even commercial grade ones for surfaces such as ceramic, concrete and masonry.

- Conveyor channel cleats: Slip-proof these surfaces with cleats that provide firm footing on most types of grating mesh conveyor ramps, platforms or walkways (even those with a sharp incline).

You’ve probably even seen anti-slip products during your daily routine and haven't really noticed them placed on:

- Transport and logistics vehicles

- Trains and station platforms

- Emergency service vehicles

- Construction and mining machinery

- Food production equipment

- Weighbridges

- Skateboards

They’re even on infrastructure projects, such as:

- Bridges

- Dams

- Tunnels

Anti-slip products are also widely used in various areas in civil aviation and the agriculture sector.

We’re guessing there’s a big chance you’ll need an anti-slip solution for your business.

In the meantime, here are some easy things that you can do quickly to prevent slips:

More anti-slip FAQs

The safe surfaces industry is one of the most important sectors in the safety market for protecting workers, visitors, contractors and all pedestrians from incident and injury due to a slip, trip, stumble, tumble or a fall.

Anti-slip products come in a wide variety of shapes, sizes, colours, coarseness grades and are required to achieve a multitude of different results, such as:

- Safety

- Compliance requirements

- Visibility

- Aesthetic

- Covering of an aging or worn surface

Do you need different kinds of anti-slip for indoor and outdoor use?

Primarily, you will consider the level of safety that the anti-slip product can provide. There are instances where indoors is harsher and has more slip hazards, especially in workplaces where floors often get liquid spills. In this case, the level of coarseness will make all the difference.

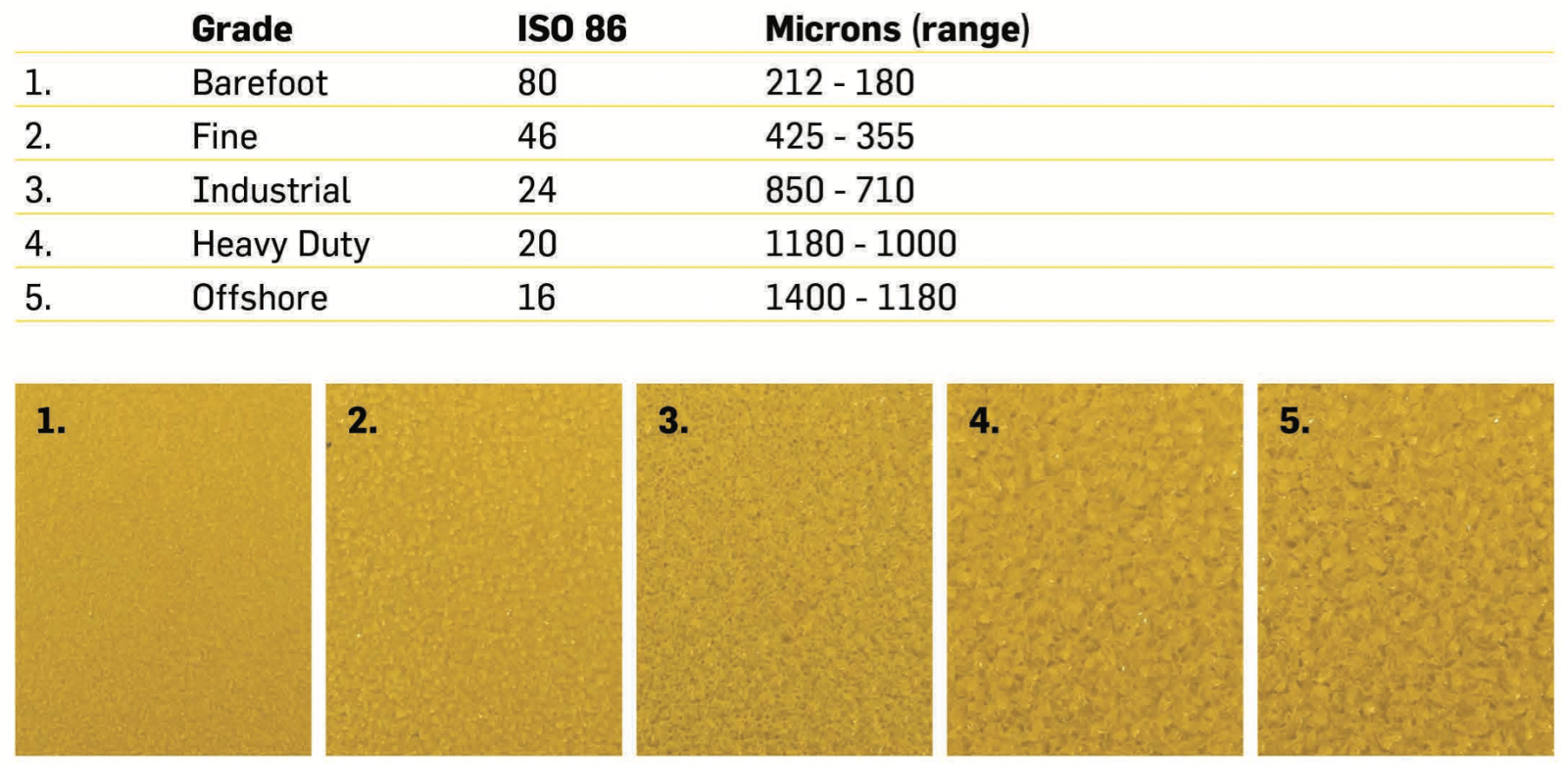

Which level of coarseness (grade) is right for my intended use?

Consider the types of pedestrians that need to be kept safe from a possible slip, stumble, trip, tumble, falter or fall.

|

Grade |

Generally used in |

|

Barefoot – 80 ISO (86) |

Areas where people may walk around in bare feet or in open-toed footwear, and there is no excess buildup of dirt, dust or debris, such as in child care centres, playground areas, picnic grounds and community pools

|

|

Fine – 46 ISO (86) |

|

|

Industrial – 24 ISO (86) |

Commercial or light industrial applications where an increased level of safety is required, such as at educational institutions, walkways and ramps for people with a disability, some residential applications and public transport infrastructure |

|

Heavy Duty – 20 ISO (86) |

Industrial applications where workers and visitors need a superior level of safety when traversing all types of pedestrian access areas, due to the possibility of an excess of dirt, dust, debris or spillage of product in trafficked areas around the workplace |

|

Offshore – 16 ISO (86) |

Applications where there is a high accumulation of, or the presence of carbon greases, heavy oils, or increased spillages on a stairway, walkway, platform or landing need the highest level of safety surface |

When installed to manufacturer guidance, standard metal-backed anti-slip products would generally have beads of silicone adhesive applied to bond the metal to the substrate. That, in addition to a layer of laminated material and resin coating, makes the product safe from potential electrical/static conduction, according to Advance Antislip Solutions.

What are your anti-slip products made of?

According to Advance Anti-Slip Surfaces, their main range of anti-slip, metal-backed products are made from high quality, BlueScope sheet products such as Colorbond®, Galvabond®, as well as 5052 aluminium and 316 stainless steel. They also offer anti-slip tapes.

Do they corrode and rust?

The sealed surface is unlikely to corrode or rust. It’s because the foundation elements are machine pressed, sheer cut from sheet steel, and the edges are coated and sealed to protect the metal.

What about anti-slip coatings?

Applied anti-slip floor coating and slip-resistant coating products have their place in the safe surfaces industry, especially where there are extremely large square metreage areas that need to be made safe for pedestrians. They are initially very effective at preventing slips and falls; however (over time and with lots of machine cleaning), they will wear away and need resurfacing at regular intervals. They also need a lot of time to dry before pedestrians can access the area.

What kinds of liquid can your anti-slip products “resist”?

They are resistant to most solvents, petroleum products and acid solutions. High concentrations of chemical, alkali, acid, solvent or other liquid contaminant (that may be harmful to humans even when wearing safety boots with slip-resistant soles) could have an effect on the product’s hardened resin coating. Although so far, we haven’t come across an instance where the products have succumbed to such a liquid contaminant attack.

How do I keep the anti-slip products clean?

You can use a firm bristle brush/broom and mops to clean them. You can even spray them with pressurized water, too (if that’s part of your housekeeping SOP). Most readily available surfactant-based detergents can clean the non-slip surface well enough, and most diluted cleaning chemicals clean the anti-slip surface without affecting its integrity.

Avoid acid-based cleaning chemicals with high concentrations of acidic components.

What are the available colours?

You can choose from our standard colour range chart. The most popular is Safety Yellow. We also offer “higher visibility” photo-luminescent (glow in the dark) Safety Yellow, Nano Green and Safety Red.

Can I relocate (reuse) the products to a different location/surface later on?

Relocating or repositioning a previously installed metal-backed anti-slip product is possible if it is removed from its existing location without sustaining any damage. If you intend to reposition them on a similar surface, there should be no potential issues, although a quick check with us to confirm the details might be wise.

AIMS’ Note on Buying Industrial Supplies

- Breadth and depth of brands and categories: Go with a supplier that offers a wide range of reputable brands across multiple categories and sub-categories.

- Bulk purchase discounts: For large orders, check if you can take advantage of volume leverage. Some suppliers offer business accounts* that give you access to special pricing (volume discounts), preferential support and even credit eligibility (subject to supplier approval, terms and conditions).

- Product and service information: Evaluate the completeness and usefulness of data in their online product listings. Prudent suppliers will include as much useful information as possible to help you assess and compare products. In terms of service info, the supplier’s FAQs (if any) will give you a good idea of their standard policies*, processes and commitments.

- Promotions: Check for ongoing promotional campaigns so you can get the best prices. Many suppliers run regular discount-based promos. Some can point you to government-hosted rebate programmes like the SafeWork NSW $1000 Small Business Rebate.

- Safety compliance: Make sure the product in question meets Australian safety standards and regulations, especially if there are relevant compliance requirements or work health and safety (WHS) laws that apply to your business or state. Look for relevant certifications and markings where necessary.

- Supplier reliability: Choose reputable suppliers with a proven track record of delivering quality products and reliable customer service.

- Warranty and support: Check warranty terms and after-sales support* options, as this can be crucial in case of product defects or performance issues.

- Lead time and availability: Confirm product availability and estimated delivery times to avoid delays in your projects.

- Returns: Familiarise yourself with the suppliers returns and exchange policy in case you receive incorrect or damaged items.

- Delivery: Clarify delivery terms, including estimated delivery times, shipping costs and who handles insurance during transit (where applicable).

*Need help with a purchase decision? Contact us directly via chat or send an email to sales@aimsindustrial.com.au.

.png)