Quick Guide to Choosing an Electric Motor

.png)

Shopping for electric motors can be tricky. There are just too many details and specifications which you must be certain of when looking for one.

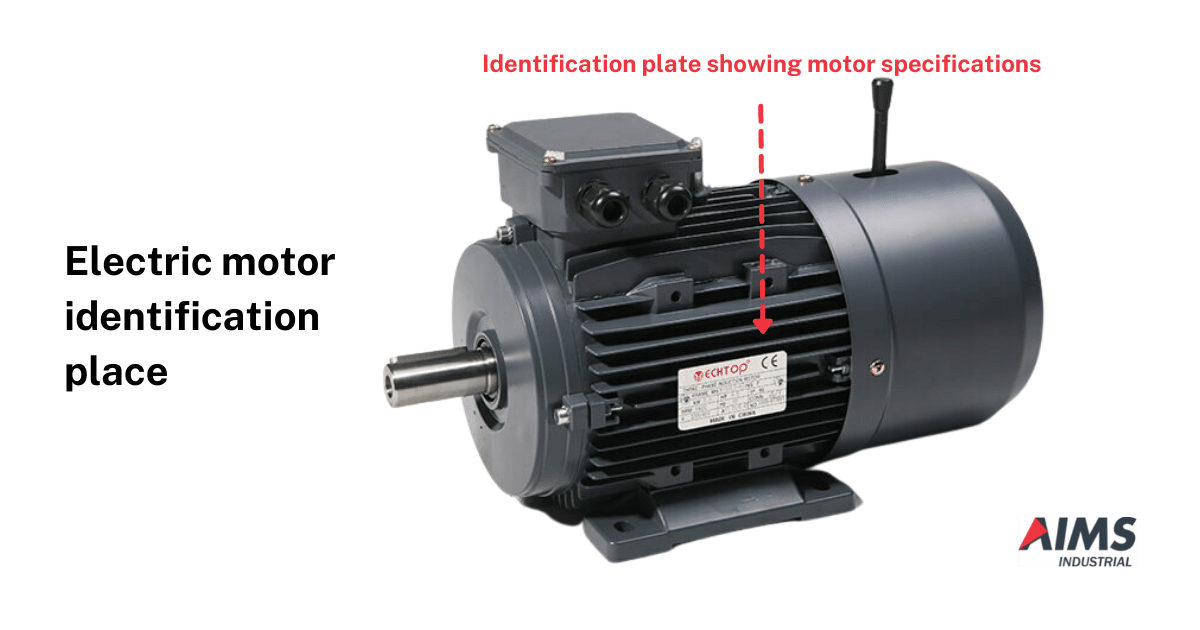

Of course, the easiest scenario is that you have the motor you want to replace, and you just provide the vendor with the motor’s identification plate which is usually affixed to the side.

Shown is the ID plate for a TechTop TA2B0223TAI aluminium motor

Most motors have such a plate that has important specifications, including:

- Power/current requirement (AC or DC)

- Power type (single phase or three phase)

- Material (cast iron vs cast aluminium)

- Speed rating

- Power rating

Some information, such as mounting options (foot vs flange, or both), are typically added post-manufacturing, as they could vary depending on the customer order. Therefore, you can’t rely on the identification plate for that information.

This article walks you through the questions to point you in the right direction when choosing an electric motor, when you should consider:

- Average lifespan of an electric motor

- Power requirement (AC or DC)

- Power type (Single-phase or three-phase)

- Material (Aluminium or iron)

- Speed rating

- Power rating

- Shaft diameter and length

- Mouting position

- Manufacturer nomenclature

- Other important considerations (rotational direction, motors for hazardous areas, brakes etc)

- More reminders

Average lifespan of an electric motor

Studies generally indicate an average lifespan of over 12 years for some motor types under normal operating conditions. Nevertheless, it depends heavily on several factors, such as:

- Type of motor

- Kilowatt / Horsepower rating relative to load

- Usage

- Operation conditions

- Maintenance

- Voltage imbalances and fluctuations

Read more about them in detail in these supplementary articles about:

Is it an AC or DC motor?

The most apparent difference, as the names suggest, is the type of current that powers the motor.

Alternating current (AC) motors:

- Are known for their high efficiency

- Are quieter and more flexible

- Are available in single-phase and three-phase configurations

- Convert energy from magnetic fields (from the coils)

In comparison, direct current (DC) motors:

- Are known for their output range

- Are capable of running at variable speeds

- Are available only in single-phase configuration

- Convert energy from external power sources with constant voltage, such as batteries

We sell a wide range of AC induction motors from TechTop Australia. Here’s their latest catalogue.

Is it a single-phase or three-phase AC motor?

Generally, single-phase motors:

- Run on a single-phase power source

- Are simpler and easier to build and maintain

- Are commonly used in light household and consumer and industrial applications with lower power requirements (eg. conveyors, fan pumps, fans, washing machines, pumps)

In comparison, three-phase motors:

- Run on a three-phase power source

- Are more complicated and harder to build and maintain

- Are commonly used in heavy duty commercial and industrial applications with higher power requirements (eg. driving lathes, cranes, agitators, crushers)

In addition, there are dual voltage motors that:

-

Are designed to use either of two stated voltages (usually 240 V and 480 V) but are wired differently to maintain the motor output

-

Are commonly used in country areas where 240V is not available, so they have the option to take one of the three phases from the mains supply and run with a neutral to get 480V

Do you prefer cast aluminium or cast iron?

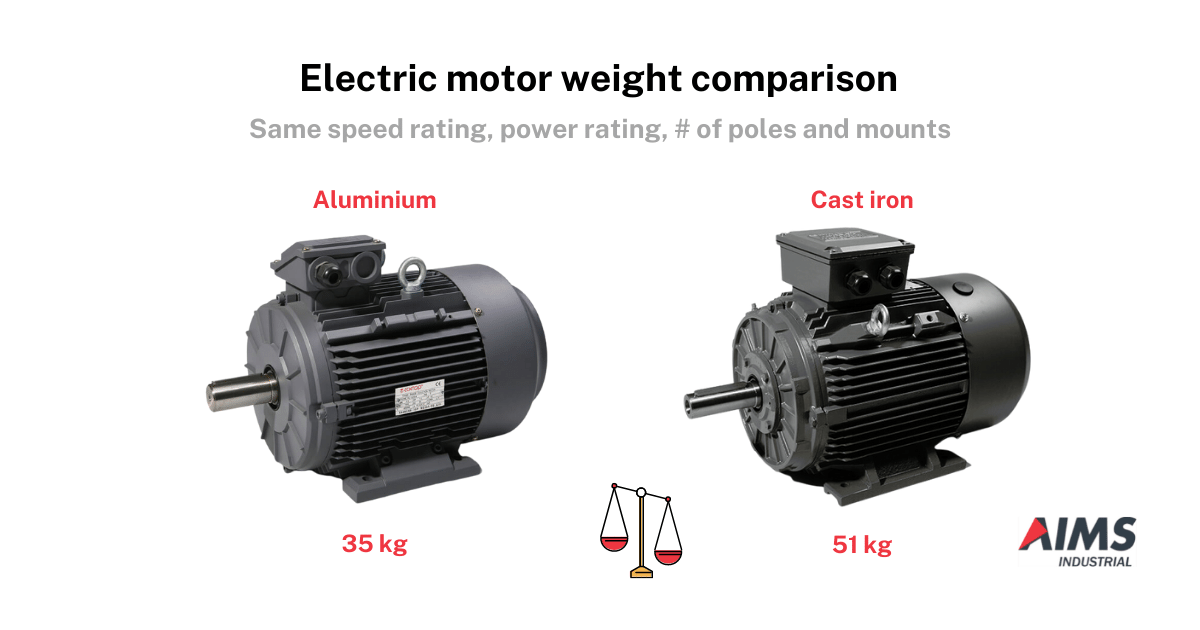

Cast aluminium electric motors:

- Are aesthetically more pleasing

- Have better heat dissipation

- Corrode less easily

- Are lighter and easier to install

In comparison, cast iron electric motors:

- Are made of more robust casing/shell, thereby able to take much more of a “beating”

- Have higher mechanical strength

- Known to last much longer

- Are heavier and harder to install

Consider these two remarkably similar motors in terms of specifications, and how one (the cast aluminum motor) is significantly lighter than the other (the cast iron motor).

What’s the speed rating?

The speed of a motor is derived from its frequency rating and the number of poles it has. This is rated by the number of revolutions per minute (RPM).

Generally, the more poles (or pole pairs), the slower the speed of the motor, but the greater its torque.

For example, a 2-pole motor will be twice as fast as a 4-pole one, which will be twice as fast as an 8-pole one, and so on.

To calculate rated RPM:

[120 x Frequency] ➗ # of poles

So, using the Australian standard of 50 Hz, the speed of a 2-pole motor is:

[120 x 50 Hz] ➗ 2 = 3,000 RPM

That of a 4-pole motor:

[120 x 50 Hz] ➗ 4 = 1,500 RPM

That of an 8-pole motor:

[120 x 50 Hz] ➗ 8 = 750 RPM

Also, it’s important to note the difference between synchronous and operating speeds:

- Synchronous speed: The speed of the motor as it is, with no load. (This is the one we calculated above, using the AU standard frequency of 50 Hz.)

- Operating speed: The speed of the motor under load.

*Using an automotive analogy, synchronous speed is like brake horsepower (engine power measured at the flywheel), while operating speed is like wheel horsepower (engine power measured at the wheels, factoring in inertia, power transmission inefficiencies and vehicle weight).

Important: If you have a three-phase motor and you want to operate the machine at different speeds, you’ll need a variable frequency drive (sometimes called a variable speed drive). As suggested by the name, it controls the frequency of the electricity powering the motor, which, together with the number of poles, dictates the speed of the motor.

Otherwise, you will have to use a gearbox to alter the speed.

The rule of thumb is that you should go no more than +/- 20% of the rated speed. So, for instance, you should not run a motor rated at 3,000 rpm any faster than approximately 3,600 rpm or any slower than approximately 2,400 rpm, or you’ll damage it.

Speed rating is a critical factor when choosing a motor, as is the power rating.

What’s the power rating?

This number tells you the output capacity of the motor, or the amount of work that can be completed in each amount of time. In terms of small electric motors, this is (often) rated in kilowatts and horsepower.

*Here’s a kilowatt-horsepower calculator for your convenience.

Of course, this is not to be confused with torque, which is the actual rotary force produced by the motor – the one that turns the shaft. Torque is quantified in Newton metres (Nm).

To emphasise, aside from speed rating, power rating is the other critical factor when deciding which electric motor to choose.

What is the shaft diameter and length?

In terms of compatibility, proper fitting and alignment of the shaft with the component to be moved (eg. fan, pulley, etc) is critical to the function, safe operation and life span of the electric motor.

In general:

- Short length but large diameter shafts can spin more torque but rotate slower (less speed)

- Long length but short diameter shafts can spin less torque but rotate faster (more speed)

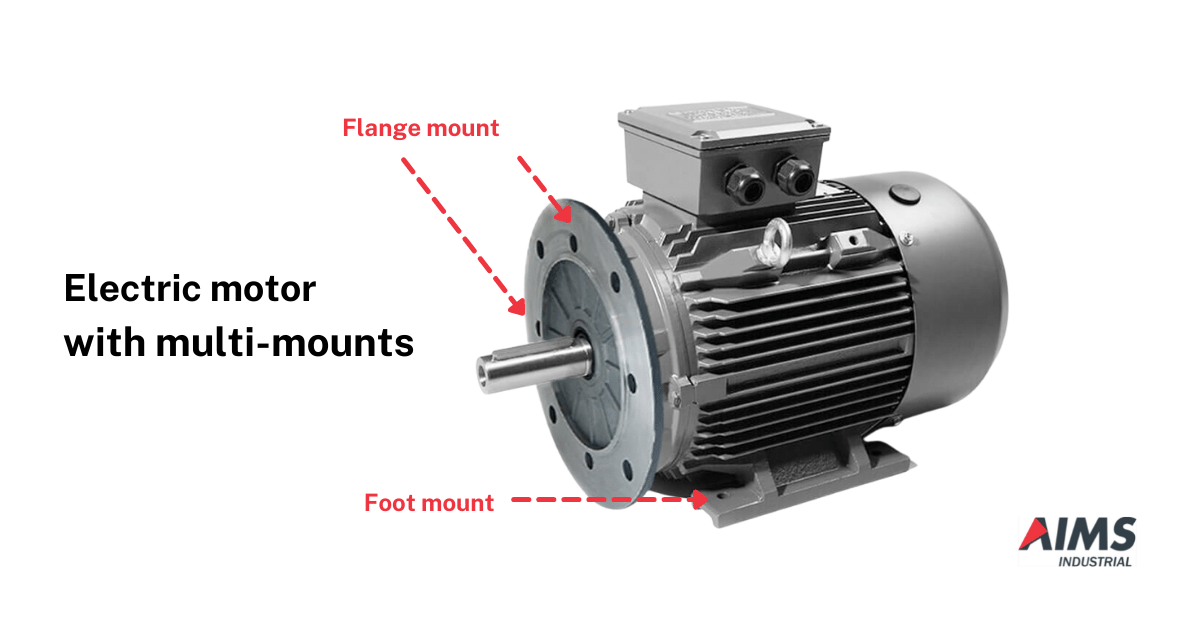

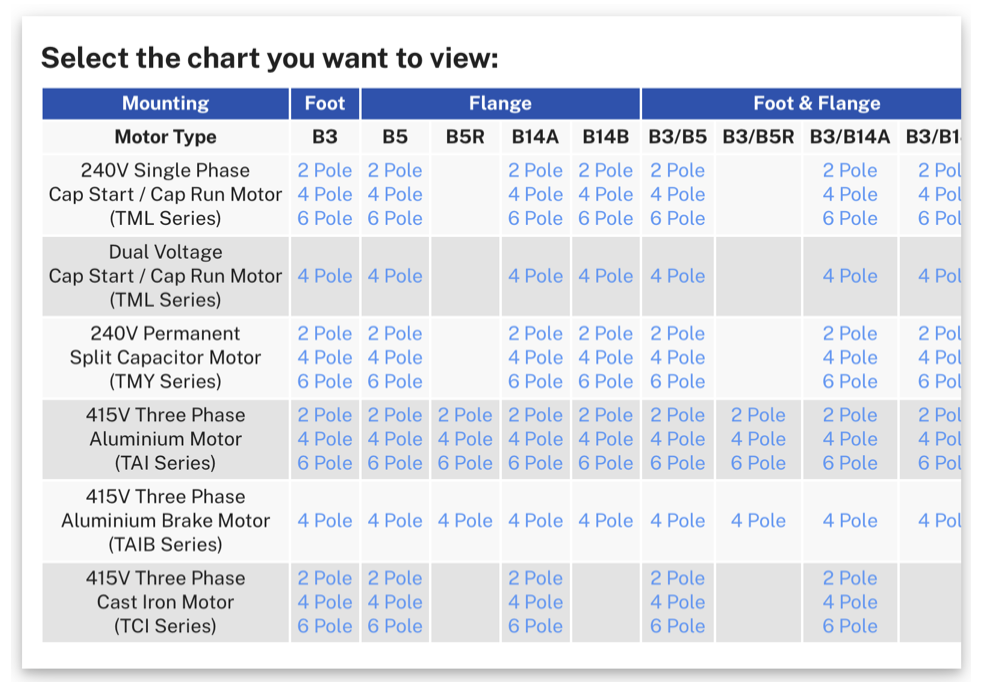

What’s the mounting position?

This tells you how the electric motor can be installed.

Here are the most common examples:

- Foot mount

- Flange mount (sometimes called a face mount)

- Multi-mount (foot and flange mounts)

On the TechTop motors we sell, the foot mount can be repositioned to the side of the motor, so it is installed with the terminal box on the side instead of the top, as shown in the image.

On the TechTop motors we sell, the foot mount can be repositioned to the side of the motor, so it is installed with the terminal box on the side instead of the top, as shown in the image.

According to the TechTop Installation and Maintenance Manual, the motors should ideally be mounted to a rigid base to prevent excessive vibration. Shims may be used if the foundation is uneven and should be placed next to and between the motor mounting bolts.

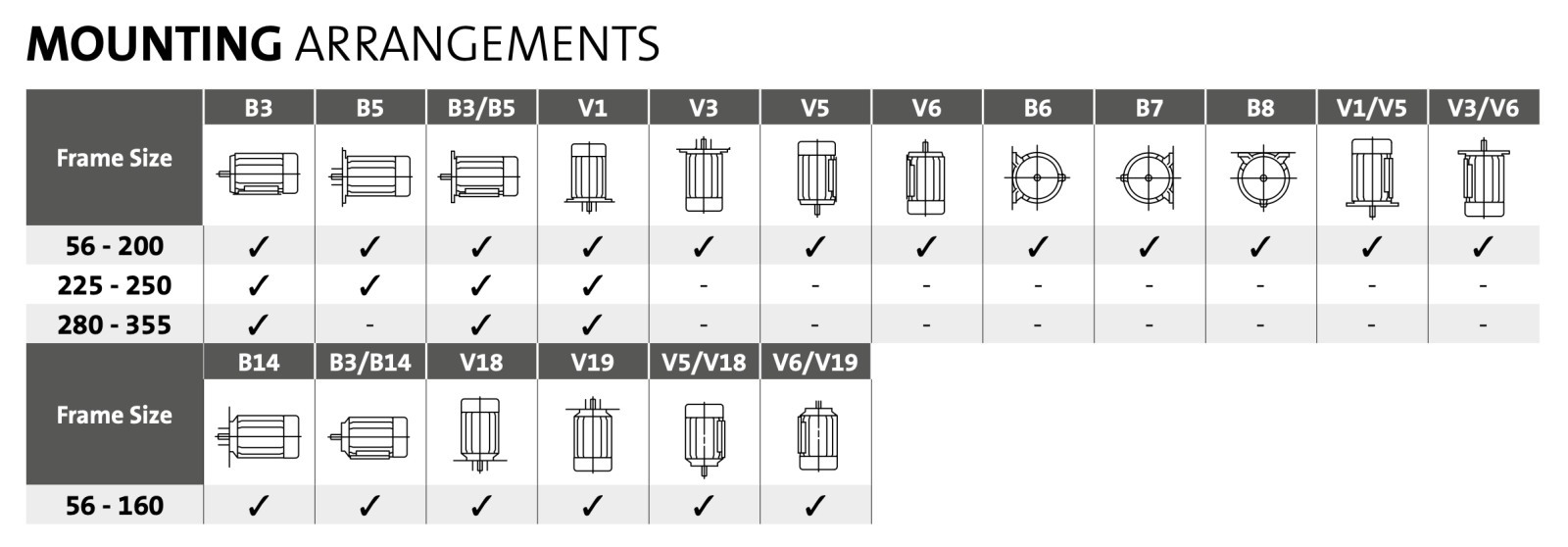

*Mounts and size chart (page 28 of the TechTop catalogue)

Important: Installation must only be done by qualified personnel. When improperly installed or used, rotating equipment can cause serious or fatal injury. As always, please refer to the installation manual.

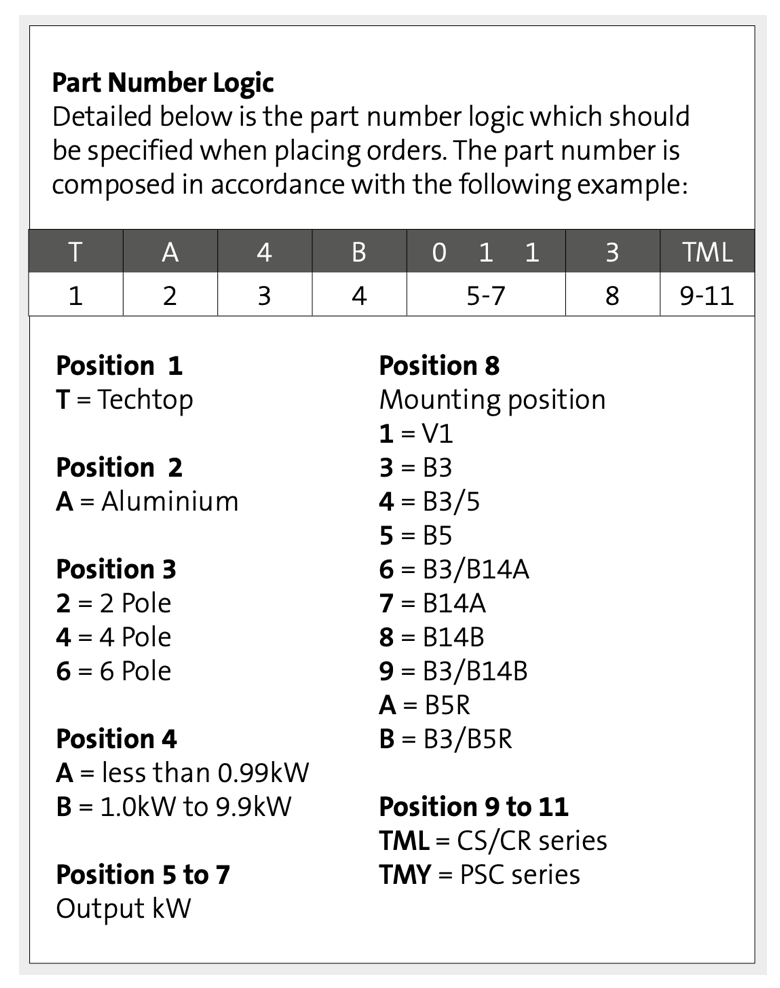

Mind the manufacturer nomenclature

Keep in mind that different manufacturers may use different nomenclature when labeling their motors.

Below is an example from TechTop motors:

*Shown is the part number logic for the TechTop TM Series of aluminium single-phase motors

Specific considerations when buying TechTop motors:

- Capacitor Start (CS) / Capacitor Run (CR): Without getting too technical, that essentially tells you that the motor uses two parallel-connected capacitors, each rated according to how they control torque values upon starting and while the motor is running. These motors are sometimes called two-value capacitor motors for the reasons just mentioned. Colloquially, they are often simply referred to as Cap Start/Cap Run. Cap Start/Cap Run motors are typically used where the motor is expected to be turned on and off regularly (eg. a lathe).

- Permanent Split Capacitor (PSC): This has only one capacitor used in the operation of the motor, and it is connected in the circuit “both at the starting and running conditions”. These motors are typically used where the motor will be turned on and then run for extended periods. For example, where a fan is turned on at the beginning of a shift and then only turned off 8 hours later. These are often used in fan and pump applications.

Important: Choose the correct option for your application as motors used in the wrong application will fail quickly.

Other important considerations

- Most motors are designed to be unidirectional, meaning they can rotate only in one direction: either clockwise (CW) or counterclockwise (CCW), depending on how it’s wired up.

- Some motors are designed to be bi-directional (can rotate both clockwise and counterclockwise), and even self-reversing.

- Some motors are specially designed to be used in hazardous areas where there are increased risks of explosion occurring. One such example is TechTop’s TCD YBX3 series of flameproof motors “Ex d”, which is certified for use in Zone 1 hazardous areas and conforms to IEC60034 and IEC60072 standards. Other popular designs include non-sparking motors (Ex nA) and dust ignition protected motors (Ex tD).

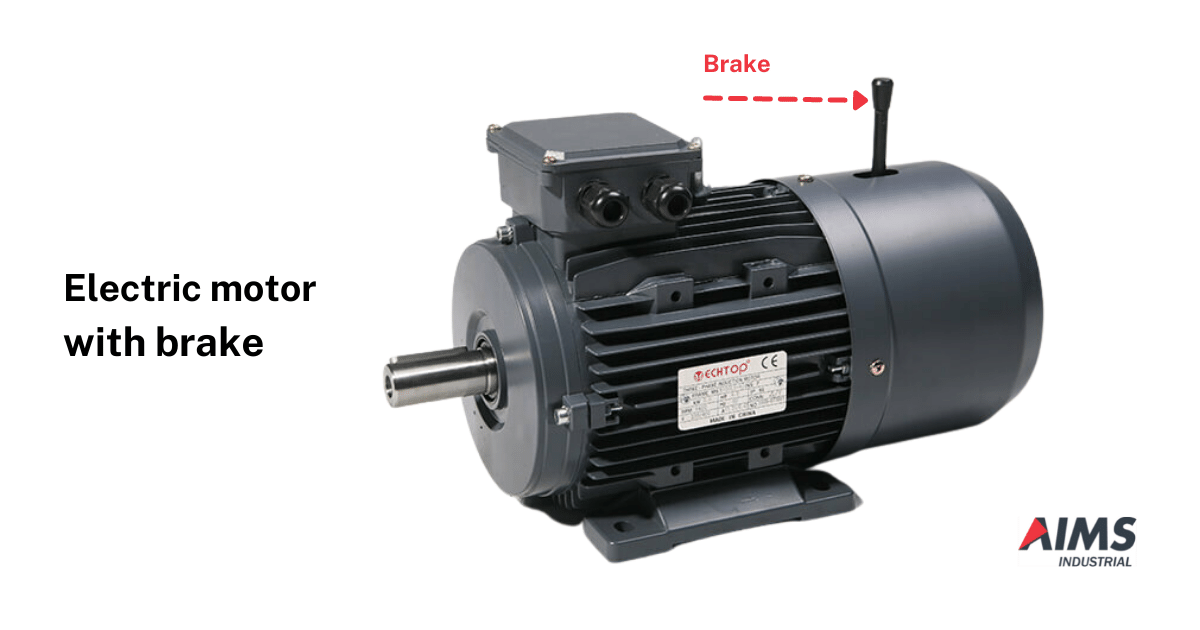

- Some motors have brakes designed to hold the load in case the shaft stops turning.

More reminders

Make sure:

- The motor is protected against (ingress of) dust particles and liquids upon installation and during operation

This refers to the ingress protection (IP) ratings of the motor, which is particularly important in some use cases, such as in marine and mining applications. It is possible to have the motor upgraded to higher IP ratings as needed. The TechTop motors we sell are mostly IP55: protection against dust limited ingress (no harmful deposit) and low-pressure jets of water from all directions.

Read more about electric motor IP ratings.

- Electric connections are solid and continuous, and circuit breakers, fuses and protective devices are compatible and rated accordingly to work with the motor -- especially during starting operations and under full motor load

- Starter and overloads are set with correct trip and load ratings

- There are no loose objects on the motor or within the fan/pulley cow

Do not:

- Obstruct the cooling system or air meant to keep the motor running at safe operating temperatures.

- Mate the motor with an inappropriate pulley, fan and/or gearbox.

Refer to our motor selection guide for more details.

AIMS' Note on Safe Use of Belt-Driven Systems

- Power down: Before any inspection, maintenance, or adjustment, make sure to completely shut down the power to the machine and apply a lockout/tagout (LOTO) device to prevent accidental restarts.

- Right belt for the system: Keep in mind that v-belts (especially cogged / notched / wrapped belts) are different from synchronous /timing / ‘toothed’ belts. Some mistake the cogs for teeth but remember that cogged belts run on V-shaped pulleys that do not have teeth. Are you operating where flammable substances are present? Maybe you need fire-resistant anti-static (FRAS) belts – or maybe heat-resistant and oil-resistant belts will do. We compared them in this FAQ.

- Safe attire: Avoid loose clothing, jewelry and long hair that could get caught in the moving parts. Ensure proper fit of workwear without compromising comfort, dexterity and protection. Tie back long hair and secure loose items.

- Safeguards in place: Never operate a belt-driven system with the guards removed or bypassed. These guards are there for your protection.

- Maintenance and replacement: Regularly inspect belts and pulleys for wear and tear. Maintain proper belt tension and alignment as specified by the manufacturer. When replacing the belt, make sure you get the proper fit and measurement of the system. These accessories and maintenance kits (eg alignment tools, belt measurers, pulley gauge sets, spacers, tensioners etc) come in handy.

- Cleanliness: Keep the area around belt drives free of debris and clutter that could get caught or cause a fire hazard.

(Refer to our content library's sub-index of articles about belt-driven systems and electric motors for more information.)

.png)