Fastener Reference Guide (Metric-Imperial Equivalents)

%20V1_5.png)

When it comes to identifying fastener sizes, thread is key. You have to know when you are dealing with metric or imperial fasteners. From there, you can cross-reference from the table below, which contains data diligently compiled from verified sources.

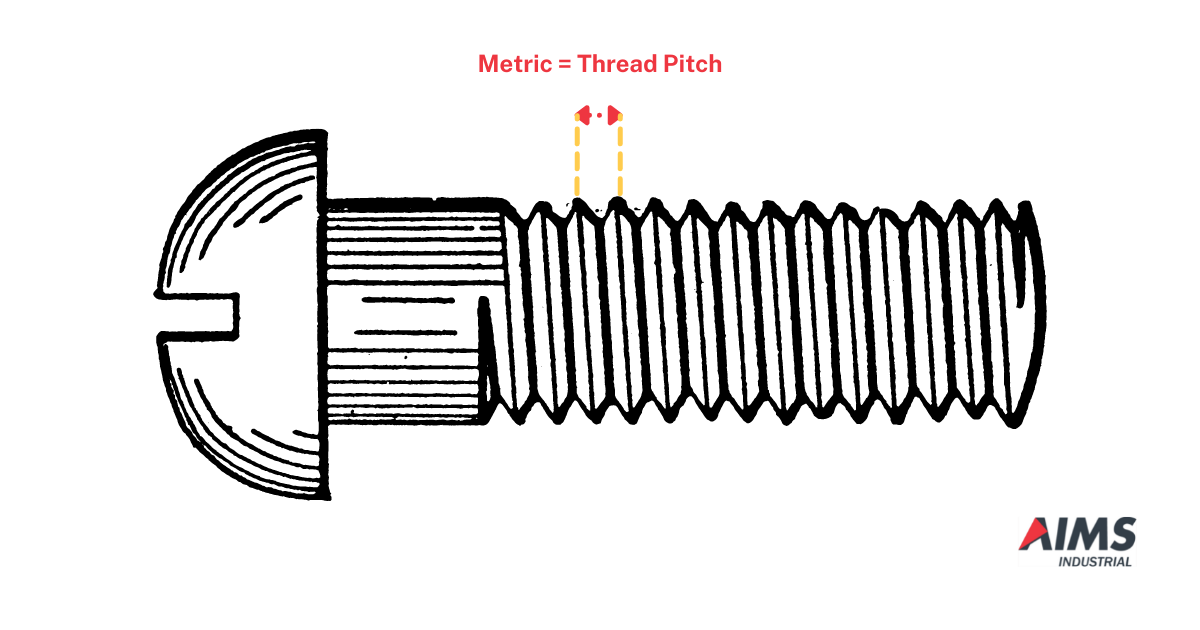

Metric fasteners use thread pitch

Thread pitch is the distance from one thread to the next (adjacent thread). It is expressed in millimetres.

Metric fasteners are typically prefixed by an M, which makes them easily distinguishable from imperial fasteners.

Thread patterns are classified as either coarse (longer) or fine (shorter) pitch.

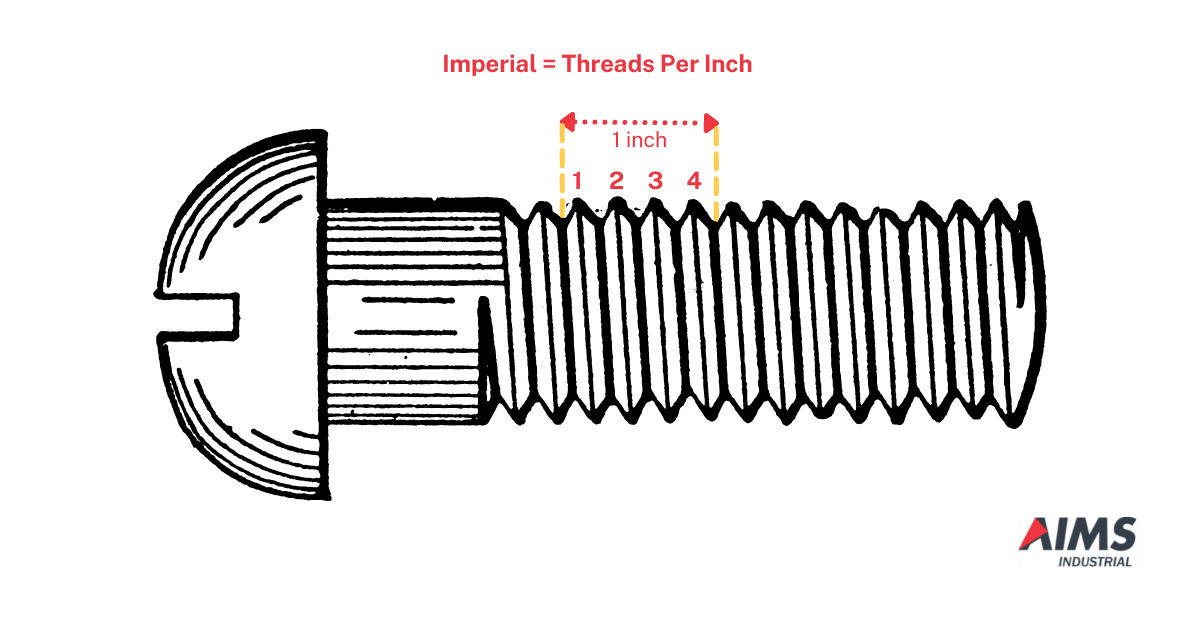

American and British fasteners use threads per inch

Threads Per Inch (TPI) is the number of threads in an inch.

When dealing with threaded fasteners from North America, you'll refer to them in Unified Thread Standard (UTS) that use:

-

Unified National Coarse (UNC) - Coarse threads*, lower TPI values

-

United National Fine (UNF) - Fine threads*, higher TPI values

You may also encounter threaded fasteners from the UK that still use the British Standard:

-

British Standard Whitworth (BSW) - Coarse threads*

-

British Standard Fine (BSF) - Fine threads*

-

British Association (BA) - Typically suffixed with BA

*Labeled in fractional inches (eg. 1/8”) based on nominal size

Metric vs Imperial equivalents

Refer to this table when cross-referencing your bolt, nut or screw. Not all metric fasteners have imperial equivalents, and vice versa.

| Metric (Pitch in mm) | Unified Thread Standard (Threads Per Inch) | British Standard (Threads Per Inch) | ||||||||

| Size | Coarse (mm) | Fine (mm) | Size | Coarse (UNC) | Fine (UNF) | Size | Coarse (BSW) | Fine (BSF) | BA | |

| -- | -- | -- | -- | #0000 | -- | 160 | -- | -- | -- | -- |

| -- | -- | -- | -- | #000 | -- | 120 | -- | -- | -- | -- |

| -- | -- | -- | -- | #00 | -- | 90 | -- | -- | -- | -- |

| M1.6 | 0.35 | 0.20 | -- | #0 | -- | 80 | -- | -- | -- | -- |

| M2 | 0.40 | 0.25 | -- | #1 | 64 | 72 | -- | -- | -- | -- |

| -- | -- | -- | -- | -- | -- | -- | 1/16" | 60 | -- | -- |

| -- | -- | -- | -- | #2 | 56 | 64 | 8BA | -- | -- | 59.1 |

| M2.5 | 0.45 | 0.35 | -- | #3 | 48 | 56 | -- | -- | -- | -- |

| -- | -- | -- | -- | -- | -- | -- | 3/32" | 48 | -- | -- |

| -- | -- | -- | -- | #4 | 40 | 48 | 6BA | -- | -- | 47.9 |

| M3 | 0.50 | 0.35 | 1/8” | #5 | 40 | 44 | 1/8" | 40 | -- | -- |

| M3.5 | 0.60 | 0.35 | -- | #6 | 32 | 40 | 4BA | -- | -- | 38.5 |

| -- | -- | -- | -- | -- | -- | -- | 5BA | -- | -- | 43 |

| M4 | 0.70 | 0.50 | -- | #8 | 32 | 36 | 3BA | -- | -- | 34.8 |

| M4.5 | 0.75 | 0.50 | -- | -- | -- | -- | -- | -- | -- | -- |

| -- | -- | -- | -- | -- | -- | -- | 2BA | -- | -- | 31.4 |

| M5 | 0.80 | 0.50 | 3/16” | #10 | 24 | 32 | 3/16" | 24 | 32 | 32 |

| M5.5 | -- | 0.50 | -- | -- | -- | -- | -- | -- | -- | -- |

| -- | -- | -- | -- | #12 | 24 | 28 | 1BA | -- | -- | 28.2 |

| M6 | 1.00 | 0.75 | -- | -- | -- | -- | 0BA | -- | -- | 25.4 |

| -- | -- | -- | 1/4" | -- | 20 | 28 | 1/4" | 20 | 26 | -- |

| M7 | 1.00 | 0.75 | -- | -- | -- | -- | 9/32" | -- | 26 | -- |

| M8 | 1.25 | 1.00 | 5/16” | -- | 18 | 24 | 5/16" | 18 | 22 | -- |

| M9 | 1.25 | 1.00 | -- | -- | -- | -- | -- | -- | -- | -- |

| M10 | 1.50 | 1.25 | 3/8” | -- | 16 | 24 | 3/8" | 16 | 20 | -- |

| M11 | 1.50 | 1.00 | -- | -- | -- | -- | -- | -- | -- | -- |

| -- | -- | -- | 7/16” | -- | 14 | 20 | 7/16” | 14 | 18 | -- |

| M12 | 1.75 | 1.25 | 1/2" | -- | 13 | 20 | 1/2" | 12 | 16 | -- |

| M14 | 2.00 | 1.50 | 9/16” | -- | 12 | 18 | 9/16" | 12 | 16 | -- |

| M15 | -- | 1.50 | -- | -- | -- | -- | -- | -- | -- | -- |

| M16 | 2.00 | 1.50 | 5/8” | -- | 11 | 18 | 5/8” | 11 | 14 | -- |

| -- | -- | -- | -- | -- | -- | -- | 11/16" | 11 | 14 | -- |

| M17 | -- | 1.50 | -- | -- | -- | -- | -- | -- | -- | -- |

| M18 | 2.50 | 1.50 | -- | -- | -- | -- | -- | -- | -- | -- |

| M20 | -- | 1.50 | ¾" | -- | 10 | 16 | 3/4" | 10 | 12 | -- |

| M22 | 2.50 | 1.50 | 7/8” | -- | 9 | 14 | 7/8” | 9 | 11 | -- |

| M24 | 3.00 | 2.00 | 1” | -- | 8 | 14 / 12 | 1" | 8 | 10 | -- |

| M25 | -- | 2.00 | -- | -- | -- | -- | -- | -- | -- | -- |

| M27 | -- | 2.00 | 1 1/8” | -- | 7 | 12 | 1 1/8” | 7 | 9 | -- |

| M28 | -- | 2.00 | -- | -- | -- | -- | -- | -- | -- | -- |

| M30 | 3.50 | 2.00 | 1 ¼" | -- | 7 | 12 | 1 ¼" | 7 | 9 | -- |

| M32 | 00 | 2.00 | -- | -- | -- | -- | -- | -- | -- | -- |

| M33 | 3.50 | 2.00 | 1 3/8” | -- | 6 | 12 | 1 3/8” | 6 / 7 | 8 | -- |

| M35 | -- | 1.50 | -- | -- | -- | -- | -- | -- | -- | -- |

| M36 | 4.00 | 3.00 | 1 ½" | -- | 6 | 12 | 1 ½" | 6 | 8 | -- |

| M38 | -- | 1.50 | -- | -- | -- | -- | -- | -- | -- | -- |

| M39 | 4.00 | 3.00 | 1 5/8” | -- | -- | -- | 1 5/8” | 5 | 8 | -- |

| M40 | -- | 3.00 | -- | -- | -- | -- | -- | -- | -- | -- |

| M42 | 4.50 | 4.00 | -- | -- | -- | -- | -- | -- | -- | -- |

| M45 | 4.50 | 4.00 | 1 ¾" | -- | 5 | -- | 1 ¾" | 5 | 7 | -- |

| M48 | 5.00 | 4.00 | 1 7/8” | -- | 5 | -- | -- | -- | -- | -- |

| M50 | -- | 3.00 | -- | -- | -- | -- | -- | -- | -- | -- |

| M52 | 5.00 | 4.00 | 2” | -- | 4.5 | -- | 2” | 4.5 | 7 | -- |

| M55 | -- | 4.00 | -- | -- | -- | -- | -- | -- | -- | -- |

| M56 | 5.50 | 4.00 | 2 ¼" | -- | 4.5 | -- | 2 ¼" | 4 | 6 | -- |

| M58 | -- | 4.00 | -- | -- | -- | -- | -- | -- | -- | -- |

| M60 | 5.50 | 4.00 | -- | -- | -- | -- | -- | -- | -- | -- |

| M62 | -- | 4.00 | -- | -- | -- | -- | -- | -- | -- | -- |

| M64 | 6.00 | 4.00 | 2 ½" | -- | 4 | -- | 2 ½" | 4 | 6 | -- |

| M65 | -- | 4.00 | -- | -- | -- | -- | -- | -- | -- | -- |

| M68 | 6.00 | 4.00 | -- | -- | -- | -- | -- | -- | -- | -- |

| M70 | 6.00 | 4.00 | -- | -- | -- | -- | -- | -- | -- | -- |

| M72 | 6.00 | 4.00 | 2 3/4" | -- | 4 | -- | 2 3/4" | 3.5 | 6 | -- |

| M75 | -- | 4.00 | -- | -- | -- | -- | -- | -- | -- | -- |

| M76 | 6.00 | 4.00 | -- | -- | -- | -- | -- | -- | -- | -- |

| M78 | -- | 2.00 | -- | -- | -- | -- | -- | -- | -- | -- |

| M80 | 6.00 | 4.00 | 3” | -- | 4 | -- | 3” | 3.5 | 5 | -- |

| -- | -- | -- | 3 ¼" | -- | 4 | -- | 3 ¼" | 3.25 | 5 | -- |

| M85 | 6.00 | 4.00 | -- | -- | -- | -- | -- | -- | -- | -- |

| M90 | 6.00 | 4.00 | 3 ½" | -- | 4 | -- | 3 ½" | 3.25 | 4.5 | -- |

| -- | -- | -- | 3 ¾" | -- | 4 | -- | 3 ¾" | 3 | 4.5 | -- |

| M100 | 6.00 | -- | 4” | -- | 4 | -- | 4” | 3 | 4.5 | -- |

| -- | -- | -- | -- | -- | -- | -- | 4 1/4" | 2.875 | 4 | -- |

| -- | -- | -- | -- | -- | -- | -- | 4 1/2" | 2.875 | -- | -- |

| -- | -- | -- | -- | -- | -- | -- | 4 3/4" | 2.75 | -- | -- |

| -- | -- | -- | -- | -- | -- | -- | 5" | 2.75 | -- | -- |

| -- | -- | -- | -- | -- | -- | -- | 5 1/4" | 2.625 | -- | -- |

| -- | -- | -- | -- | -- | -- | -- | 5 1/2" | 2.625 | -- | -- |

| -- | -- | -- | -- | -- | -- | -- | 5 3/4" | 2.5 | -- | -- |

| -- | -- | -- | -- | -- | -- | -- | 6 | 2.5 | -- | -- |

Aside from the thread pitch (metric) or count (imperial), other factors to consider when buying fasteners include:

-

Type (bolt, nut or screw)

-

Head

-

Strength (classified by grade/class)

-

Material and finish (coating)

-

Tensile properties (low/high tensile)

-

Thread length (full/partial)

It’s always great to have a sample of the fastener you’re shopping for, but that won’t always be the case. We have a wide range of fastener listings with pictures that you can use for reference.

Important:

- Always consult a detailed fastener size chart for appropriate tool selection.

.jpg) You may want to consider getting the Fastener Black Book (1st Edition) for more complete information.

You may want to consider getting the Fastener Black Book (1st Edition) for more complete information.

More size charts

- Anchor Bolt Size Chart: Sort through a wide variety of metric anchor bolt types: countersunk head sleeve anchor, drop-in anchor, hex flange nut sleeve anchor, flush head sleeve anchor and stud anchor. Common metric diameters listed.

- Drill Bit Size Chart: Choose the right bit size to ensure a proper fit for your intended gauge sizing. Metric (SI) and imperial (US decimal / fractional inches) values matched.

- Loctite Application Chart: Know which Loctite product to use with various materials and surfaces, from bricks and ceramics to vinyl and wood.

- Pulley Size Chart: Sort through a wide variety of aluminium and cast-iron pulleys for different belt sections and grooves. For taper locks, pilot bores and bores with keyway. Metric and imperial sizes available.

- Socket Sizing Cross-Reference Chart (Metric-Imperial Values): Match the right (or nearest alternative) sockets and drives. Metric and imperial sizes available.

- Spanner Size Chart: Find out which spanner size to use for your bolt, nut or screw with a hexagonal head. Metric and imperial (UNC/UNF) sizes matched.

- Tapping Drill Size Chart for Thread Cutting Taps: Find the appropriate (and nearest alternative) drill size for creating a pilot hole before cutting threads in a workpiece. Common coarse and fine drill sizes listed. Metric and imperial (US decimal / fractional inches) values matched.

AIMS' Note on Safe Use of Hand Tools

- Inspection: Before using any tool, carefully inspect it for cracks, chips, loose handles, worn / mushroomed heads or any other signs of damage. Damaged or defective tools may cause harm! Ensure all guards are in place.

- Right tool for the job: Make sure you understand the intended purpose of each tool and choose the correct one for your specific job. Don't try to make a screwdriver work as a pry bar or a wrench as a hammer.

- Safe handling: Carry sharp tools pointed down and away from your body. Never carry tools in your pockets where they can cause injury. When passing a tool to someone, extend the handle first.

- PPE: Wear safety glasses or goggles to protect your eyes from flying debris. Consider gloves depending on the tool and task to prevent cuts or blisters but without compromising comfort, dexterity and protection. If working with noisy tools, wear ear protection.

- Maintenance: Keep your tools clean, sharp and properly maintained. Store them in a safe and organised place when not in use.

.png)