When to Use Which LOCTITE® Product (With Charts from Henkel)

.png)

You've probably been in a sticky situation where your glued pieces just keep on falling apart. As a reminder, it’s worth remembering that:

- There is no one-size-fits-all solution when it comes to properly bonding materials together.

- There is an appropriate adhesive to use for certain use cases (especially, industrial applications)

- Your multi-purpose adhesive won’t always cut it (the resulting bond integrity may vary because each substrate has different physical and chemical characteristics)

Speaking of adhesives, it’s hard to talk about the best brands without mentioning LOCTITE®. As a casual user, you have probably used their products to “build things and fix stuff”.

LOCTITE® is not just for casual DIYers who work on home projects. The big guys in various industries use it, too, even for tough niche applications.

In this article, we’ve compiled a host of content (mostly from Henkel) to help you choose the right LOCTITE® product for your intended use. You’ll find information about (and links to):

- Using LOCTITE® for pump maintenance

- Instant adhesives, accelerators and primers

- LOCTITE® product application guide

- General purpose vs specialty adhesive

- Threadlockers for fasteners

- LOCTITE® user guide

- Feedback from users in real-life applications

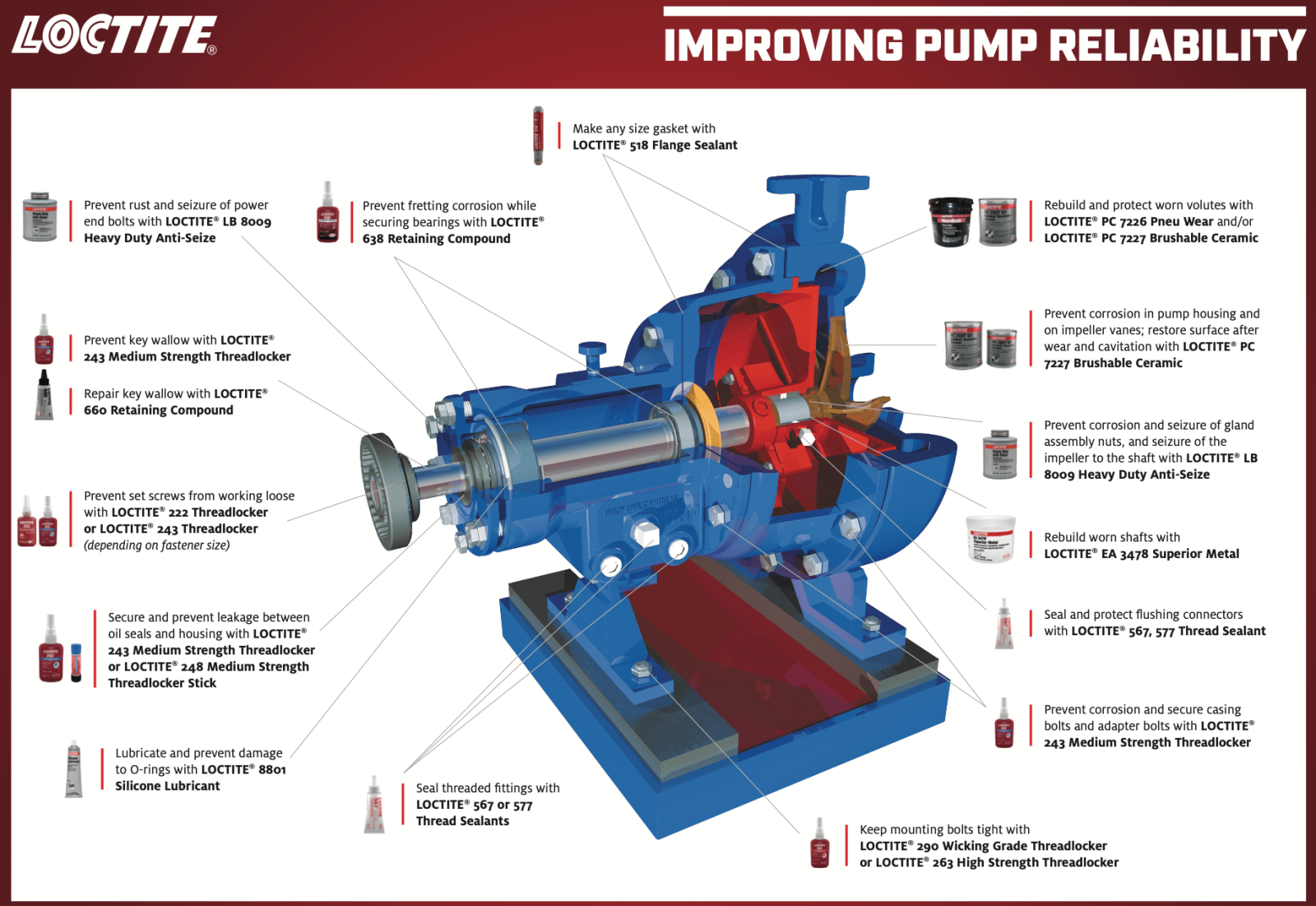

Using LOCTITE® for pump maintenance

Below is a visual guide from Henkel (and a PDF copy) that shows which LOCTITE® product to use for each part of your pump.

You can buy most of those products from our online store:

- LOCTITE® 222 Threadlocker

- LOCTITE® 243 Medium Strength Threadlocker

- LOCTITE® 248 Medium Strength Threadlocker Stick

- LOCTITE® 263 High Strength Threadlocker

- LOCTITE® 290 Wicking Grade Threadlocker

- LOCTITE® 518 Flange Sealant

- LOCTITE® 567 Thread Sealant

- LOCTITE® 577 Thread Sealant

- LOCTITE® 638 Retaining Compound

- LOCTITE® 660 Retaining Compound

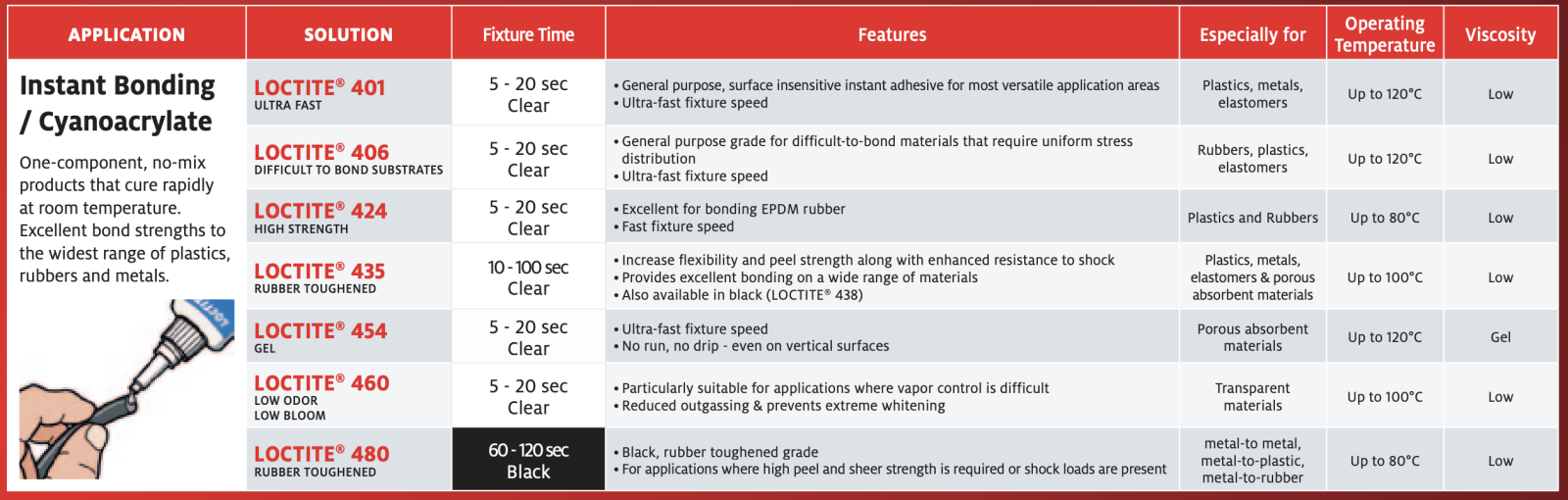

Instant adhesives, accelerators and primers

According to this LOCTITE® selector guide:

Instant adhesives are ideal for bonding small- to medium-size parts with close-fitting, smooth surfaces. They provide fast cure speeds and excellent bond strengths to a wide variety of substrates, including hard-to-bond materials.

You can use them for (almost) anything from general purpose repairs to specialty high-performance assembly applications.

|

Product |

Description |

Best used |

|

LOCTITE 401TM Surface-Insensitive, Medium Viscosity |

A fast-setting, surface-insensitive instant adhesive that provides high shear strength |

When you need a fast fix and high strength on a wide range of materials, including difficult-to-bond substrates |

|

LOCTITE 406TM Low Viscosity |

A fast-curing instant adhesive that is ideal for bonding plastics and elastomeric materials where very fast fixturing is required |

When you need to bond plastic and rubber |

|

LOCTITE 454TM Non-drip Gel |

A general purpose, non-drip gel, instant adhesive |

For overhead and vertical applications |

|

LOCTITE 460TM Low-Odor, Low-Bloom, Low Viscosity |

A low-viscosity, low-odor, low-bloom instant adhesive that rapidly bonds a wide range of materials |

To minimise bondline aesthetic or odor concerns |

|

LOCTITE 480TM Toughened, Low Viscosity |

A toughened, fast-curing instant adhesive that is ideal for bonding metal to metal, rubber or magnets, particularly in humid environments |

For heavy-duty bonding |

|

LOCTITE 3090TM Two-Component Gel |

A unique, two-part instant adhesive that provides gap filling in excess of 0.10" for a wide range of materials |

To fill large gaps |

In addition, you can use accelerators and primers:

- Accelerators speed up the cure and increase the gap fill of instant adhesives

- Primers allow for improved adhesion on hard-to-bond substrates by making polyolefin and other low-energy surfaces suitable for bonding with instant adhesives.

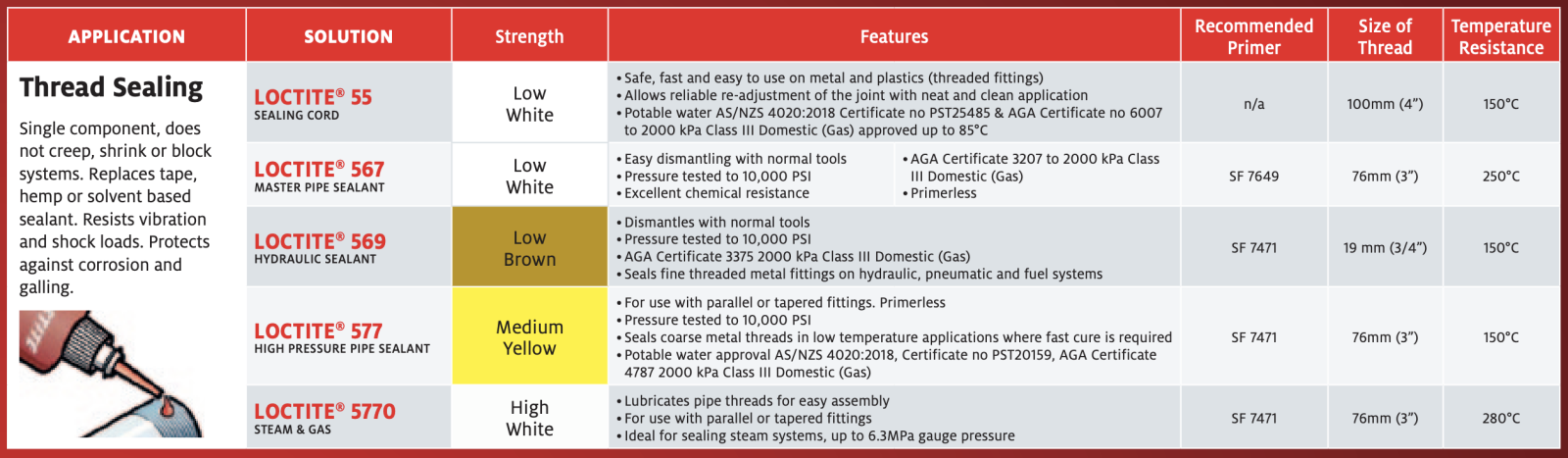

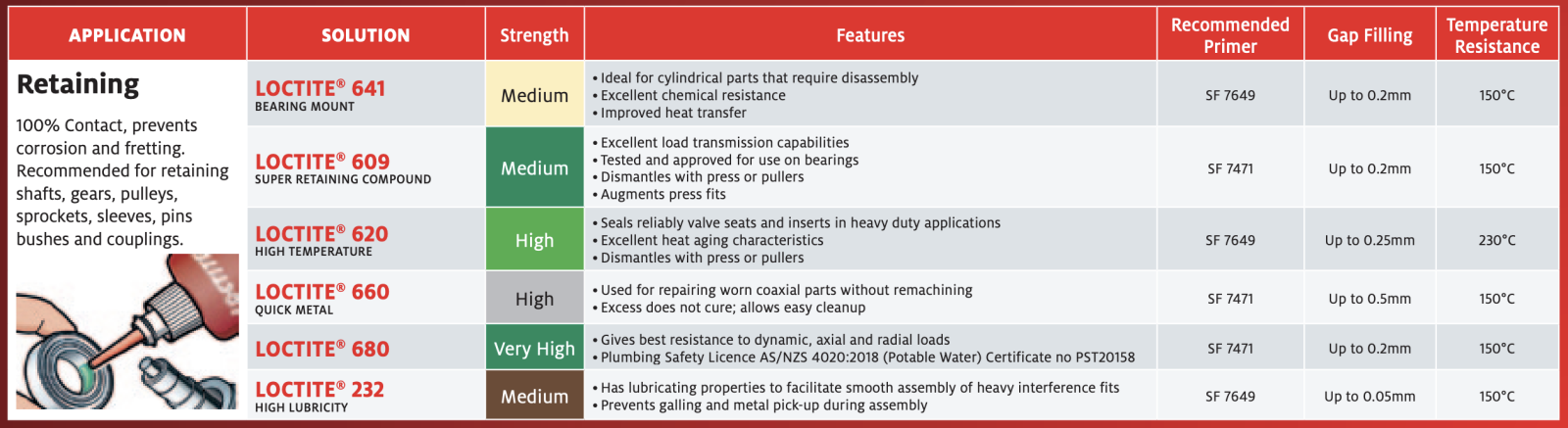

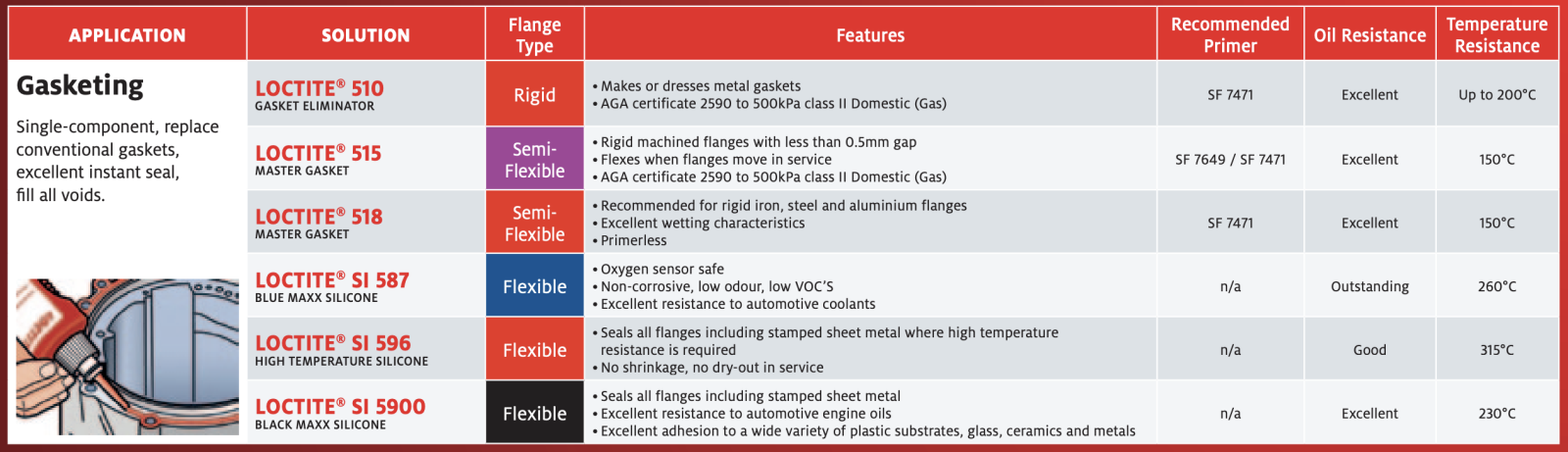

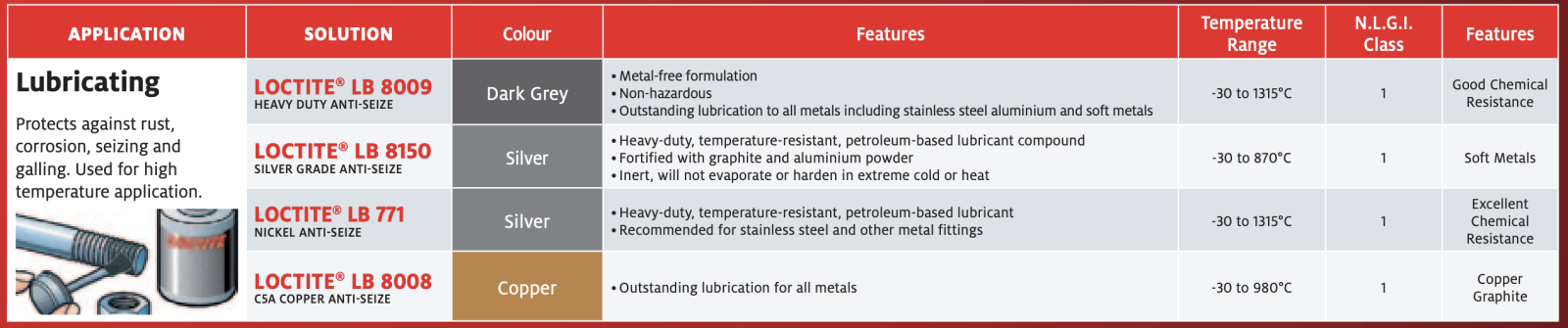

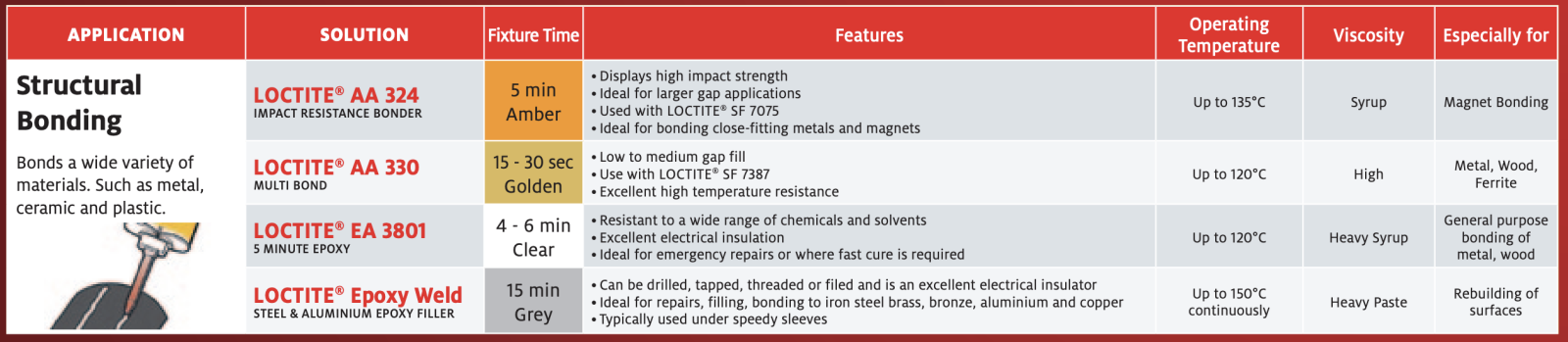

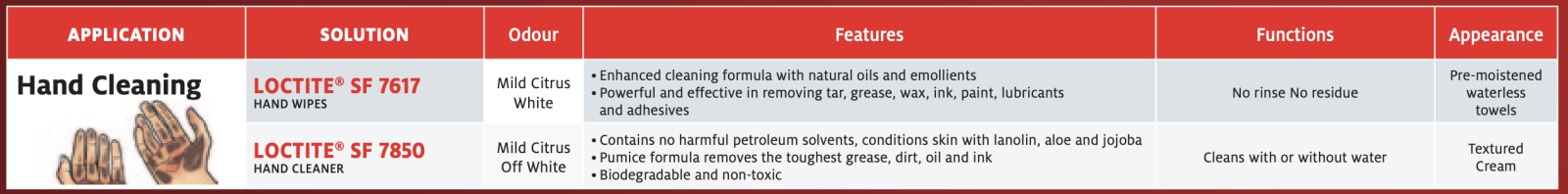

LOCTITE® product application guide

Below are snapshots taken directly from this handy PDF by Henkel. It shows us which LOCTITE® product(s) -- and recommended primers, in some instances – to use for what application, taking into consideration operating temperatures.

General purpose vs specialty adhesive

When choosing an instant adhesive, it’s important to know the different types and what they’re specifically designed for:

- General purpose adhesives are strong and versatile enough for the vast majority of applications, including acidic surfaces such as chromated or galvanized metals and porous substrates such as wood paper, leather, cork and fabric.

- Flexible adhesives are best for bonding materials subjected to bending or distortion, as well as flexible components. Use them where elasticity, pliability, and plasticity are important. The industrial grade ones are even suitable for both gap-filling and sealing techniques, as well as strong adhesion between numerous substrates, flexible adhesive solutions provide excellent curing speeds and fixing times.

- High gap fill adhesives are best for applications with gaps up to 0.15 mm. 2-K technologies provide fast cure independent of gaps up to 5 mm.

- High temperature adhesives can withstand operating temperatures up to 120 °C.

- Light cure adhesives are designed to cure very rapidly upon exposure to UV / visible light of the proper intensity.

- Low odour / low bloom adhesives are low-volatile adhesives are best for applications where cosmetic appearance, minimal frosting and low odour are required.

- Toughened / Elastomer modified adhesives are best for applications subjected to high shock, impact and humidity.

For heavy-duty and industrial applications, it’s best to refer to this list by Henkel, where they discuss these adhesives in greater detail:

- Laminative adhesives

- Optically clear adhesives

- Structural inserts

- Water-based adhesives

- Assembly film adhesives

- Die attach adhesives

- Electrically conductive adhesives

- Flexible adhesives

- Hot melt adhesives

- Pre-applied adhesives and sealants

- Pressure-sensitive adhesives

- Retaining compounds

- Solvent-based adhesives

- Structural adhesives

- Threadlockers

- UV adhesives and sealants

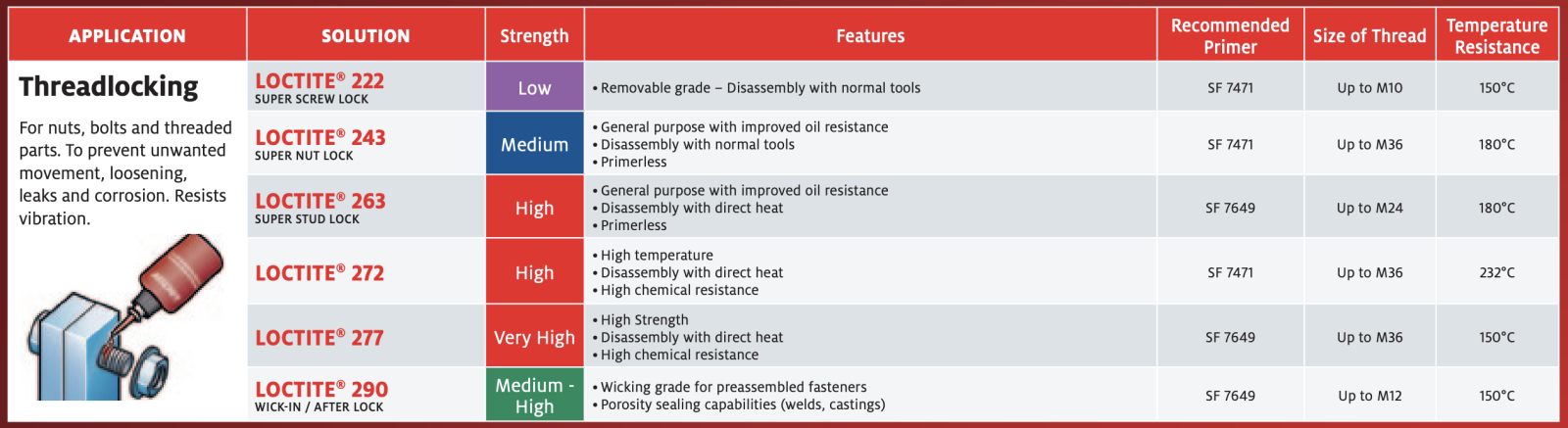

Threadlockers for fasteners

Threadlocking adhesives, such as LOCTITE® threadlockers, are formulated to “eliminate the potential of loosening, leakage and failure by locking your fasteners in place”, according to this article from Henkel.

They really make a big difference, as you’ll see in this video:

More threadlocker reminders from Henkel’s article:

- Using the wrong type of threadlocker could lead to reduced reliability, difficulties with removal and improper curing. This may impact how well your adhesive locks assemblies in place, increasing the chance of loosening and failure.

- Consider the size of the thread, as getting it wrong can make servicing or disassembly more difficult. Generally speaking, the larger your thread, the higher the strength your threadlocker needs to be.

- The ease with which a threadlocker can be removed depends on its strength.

- Low and medium strength threadlockers can be removed with standard hand tools.

- High or permanent strength threadlockers may require direct, intense heat application to disassemble.

- For high temperature applications, choose a threadlocker with higher heat resistance, such as LOCTITE® 263.

- For applications with a high risk of vibration or shock, choose LOCTITE®’s red threadlockers (just take note that, as they are the “strongest grade”, they “hold firmly in place as a permanent solution.”

- For applications where the fastener is pre-assembled (eg. electrical connects and set screws), use a wicking grade threadlocker such as the LOCTITE® 290.

LOCTITE® threadlockers come in three strength grades:

- The low-strength LOCTITE® 222 works on all metals, and is especially good for applications that may require disassembly.

- The medium-strength LOCTITE® 243 offers a good general-purpose solution to seal and secure assemblies.

- The high-strength LOCTITE® 263 is designed for permanent locking and sealing of threaded fasteners.

Speaking of LOCTITE® threadlockers, here are some myth-busters from Henkel themselves:

LOCTITE® user guide

Finally, here’s an oldie-but-goodie guide to help you "Do It Right” when it comes to using LOCTITE® maintenance products.

Feedback: Ken H from Perth shared his experience with Loctites:

"With a weapons radar fitting (gun and missile radar direction systems) background, I used all the Loctites at work, and now have a dozen different sorts in the garage that I use every day. I mainly use it in garage now (retired, 8 vehicles, mostly old ones, 1963 through to current) and it is essential; but I still have a full kit (ex work) and all the charts.

I use mostly 243 (old bikes, use on everything, currently rebuilding 1974 Triumph Trident motorcycle) 262 (engine drive train components), bearing mount (two grades, yellow and blue) , and have/use three grades of Loctite gasket. The primer (7471) is essential for oily engine "critical" components, like cam sprockets/tensioners that will never bond otherwise. My Triumph Stag and Dolomite Sprint have tiny chain tensioner bolts that have to be exact tension, (must be tight, but easy to snap) and if they loosen = catastrophic damage. Primer and 243 ONLY thing that works.

The greens should come with a warning, as if they bond properly, the average person will never get them off if they don't "get it" and use by mistake. Mainly for earthmoving/mining applications, so not mainstream.

Again, Loctite is essential to anyone serious about fastener retaining.

With skills in fitting/mech fields declining/becoming "shallower" (most just replace whole units/next higher assembly) the more info available the better.

So again, thanks for the info, and good that you provide it."

AIMS’ Note on Buying Industrial Supplies

- Breadth and depth of brands and categories: Go with a supplier that offers a wide range of reputable brands across multiple categories and sub-categories.

- Bulk purchase discounts: For large orders, check if you can take advantage of volume leverage. Some suppliers offer business accounts* that give you access to special pricing (volume discounts), preferential support and even credit eligibility (subject to supplier approval, terms and conditions).

- Product and service information: Evaluate the completeness and usefulness of data in their online product listings. Prudent suppliers will include as much useful information as possible to help you assess and compare products. In terms of service info, the supplier’s FAQs (if any) will give you a good idea of their standard policies*, processes and commitments.

- Promotions: Check for ongoing promotional campaigns so you can get the best prices. Many suppliers run regular discount-based promos. Some can point you to government-hosted rebate programmes like the SafeWork NSW $1000 Small Business Rebate.

- Safety compliance: Make sure the product in question meets Australian safety standards and regulations, especially if there are relevant compliance requirements or work health and safety (WHS) laws that apply to your business or state. Look for relevant certifications and markings where necessary.

- Supplier reliability: Choose reputable suppliers with a proven track record of delivering quality products and reliable customer service.

- Warranty and support: Check warranty terms and after-sales support* options, as this can be crucial in case of product defects or performance issues.

- Lead time and availability: Confirm product availability and estimated delivery times to avoid delays in your projects.

- Returns: Familiarise yourself with the suppliers returns and exchange policy in case you receive incorrect or damaged items.

- Delivery: Clarify delivery terms, including estimated delivery times, shipping costs and who handles insurance during transit (where applicable).

*Need help with a purchase decision? Contact us directly via chat or send an email to sales@aimsindustrial.com.au.

%20-.png)

.png)