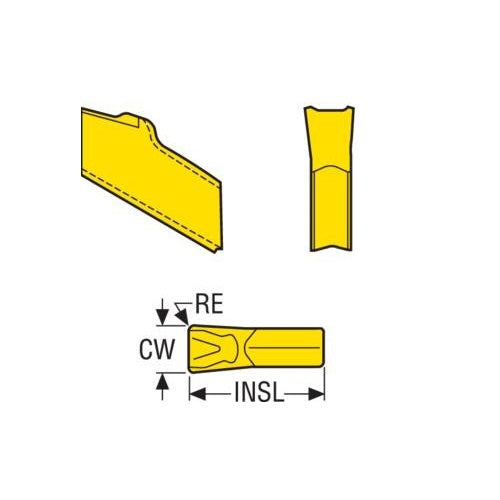

Seco T25M Disc Mill Parting Off Carbide Insert 14 Chipbreaker

Choose your option

Seco Parting Off Insert - Neutral 14 Chipbreaker

Choose your option

Seco Turning Insert CCMT Insert Style - F1 7° Grade TP2501

Choose your option

Seco Turning Insert T Shape Code 3.18 x 0.4 x 6.35mm G Insert Type - MF2 Grade TP2501 ± 0.13/± 0.05mm Tolerance TNMG110304-MF2,TP2501 - Pack of 10

Choose your option

Seco Turning Insert R Shape Code 3.5 x 3.18 x 8mm T Insert Type - F2 7° Grade CP200 ± 0.13/± 0.05mm RCMT0803M0-F2 Pack of 10

Choose your option

Turning Insert 883 Grade (TPMM)

Choose your option

Seco Turning Insert DCMT Insert Style - F1 7° Grade TP1030

Choose your option

Seco Turning Insert CCMT Insert Style - W-F1 7° Grade TP1020

Choose your option

Turning Insert SNMG Insert Style - MR3 Grade CP200

Choose your option

Seco Turning Insert DCMT Insert Style - MF2 7° PVD Coated

Choose your option

Seco Turning Insert CCMT Insert Style - M3 7° CVD Coated

Choose your option

Turning Insert HX Grade (TPUN)

Choose your option

Turning Insert TP40 Grade (TPMR)

Choose your option

Turning Insert WNMG Insert Style - M3 Grade TP2501

Choose your option

Turning Insert CNMG Insert Style - M3 Grade TP2501 3.18mm (S)

Choose your option

Seco TGP45 Disc Mill Parting Off Carbide Insert 14 Chipbreaker

Choose your option

Seco TGP45 Disc Mill Parting Off Carbide Insert 12 Chipbreaker

Choose your option

Seco CP500/CP600 Disc Mill Parting Off Carbide Insert 12 Chipbreaker

Choose your option

Carbide PVD (D14) Turbo 12 Square Shoulder Milling Insert

Choose your option

Seco Turning Insert VBMT Insert Style - F1 5° PVD Coated

Choose your option

Seco Turning Insert TCMT Insert Style - F1 7° CVD Coated

Choose your option

Seco Turning Insert T Shape Code 4.76 x 0.4 x 9.53mm G Insert Type - FF1 Grade TP1030 ± 0.13/± 0.05mm Tolerance TNMG160404-FF1,TP1030 - Pack of 10

Choose your option

Seco Turning Insert D Shape Code 4.76 x 0.4 x 9.53mm U Insert Type - MF1 Grade CP500 ± 0.13/± 0.05mm Tolerance DNMU110404-MF1,CP500 - Pack of 10

Choose your option

Seco Turning Insert T Shape Code 3.97 x 0.4 x 9.53mm T Insert Type - F1 7° Grade CP200 ± 0.13/± 0.05mm TCMT16T304-F1 Pack of 10

Choose your option

Seco 12 x 5.03mm MS2500 20.3° Chamfer Mill Turbo 12 Milling Insert XOEX120408R-M07,MS2500 Pack of 10

Choose your option

Seco 11.6 x 5.07mm MK1500 10.4° Chamfer Mill Turbo 12 Milling Insert XOMX120408TR-M12,MK1500 Pack of 10

Choose your option

Seco Turning Insert SCMT Insert Style - F2 7° CVD Coated

Choose your option

Seco Turning Insert C Shape Code 0.97 x 0.2 x 3.97mm B Insert Type 15° Grade 883 ± 0.025/± 0.025mm CDCB04T002,883 Pack of 10

Choose your option

Seco Turning Insert TCMT Insert Style - M5 7° CVD Coated

Choose your option

Seco Turning Insert VBMT Insert Style - F2 5° CVD Coated

Choose your option

Seco Turning Insert TCMT Insert Style - F2 7° CVD Coated

Choose your option

Turning Insert SCMT Insert Style - M3 7° Grade TP25

Choose your option

Turning Insert TNMM Insert Style - R4 Grade TP2501

Choose your option

Turning Insert WNMG Insert Style - M6 Grade TP2501

Choose your option

Turning Insert WNMA Insert Style Grade TK0501

Choose your option

About Indexable Inserts

Indexable inserts for milling and turning deliver precision, durability and cost efficiency for Australian workshops and manufacturing plants. Our range of carbide inserts and coated grades suits steel, stainless steel, cast iron, aluminium, titanium, hardened steel and plastics, providing reliable performance in high-speed and high-temperature conditions. Available in multiple geometries and chipbreaker designs, these inserts offer superior edge retention, improved chip control and longer tool life while reducing downtime through simple, fast replacements. Choose uncoated, PVD or CVD coated options for optimised wear resistance and heat management across roughing, finishing and heavy-duty operations. Whether you need ISO-standard sizes or specialty shapes for profiling and shoulder milling, our indexable inserts deliver consistent surface finish and dimensional accuracy. Find inserts matched to your holder, material and cutting parameters with clear grade recommendations and competitive pricing. Shop now to upgrade productivity, lower tooling costs and achieve predictable machining outcomes across production and repair environments.